Dynamic interiors with real-time twins.

Overview.

Project background.

This project introduces a groundbreaking modular, data-driven interior construction system designed for real-time component tracking, sustainability, and dynamic adaptability. Driven by a partnership among Full Stack Energy and our client, this Indoor Positioning System Solution leverages advanced Bluetooth RTLS (Real-Time Location Systems), IoT sensors, and 5G connectivity to deliver a next-generation approach to commercial interiors. Unlike traditional fit-outs, this solution views building interiors as dynamic material banks, digitally managing components to maximise reuse, minimise waste, and enhance spatial flexibility.

Commercial building interiors traditionally face significant challenges including:

- High levels of waste and embodied carbon due to disposable fit-outs.

- Inflexibility in adapting interiors to changing occupancy and operational needs.

- Difficulty in tracking components for reuse or recycling at the end of their lifecycle.

- The absence of real-time spatial and environmental analytics to inform adaptive reuse and sustainability initiatives.

Full Stack Energy's

Solution.

Key technical highlights:

- Modular SmartGrid Infrastructure: The client developed the SmartGrid—a ceiling-mounted, modular aluminium framework allowing precise installation, rapid reconfiguration, and high-value reuse of interior components including partitions, doors, and lighting.

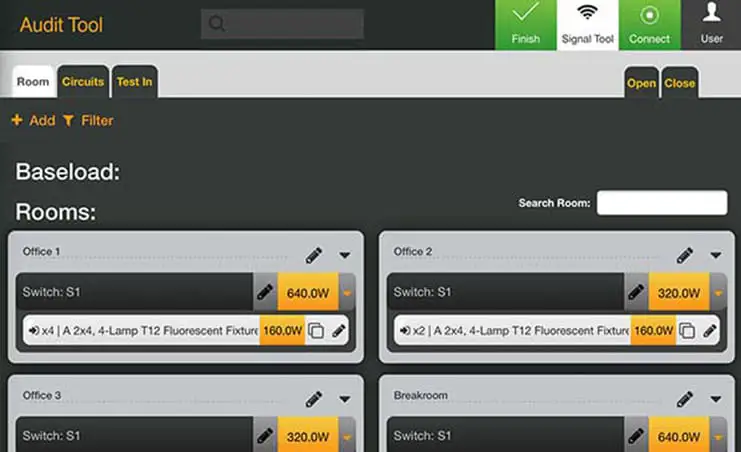

- Bluetooth CTE RTLS Technology: Full Stack Energy created custom Bluetooth tags and anchor point systems, leveraging Bluetooth 5.1’s Constant Tone Extension (CTE) for precise spatial tracking. This technology creates accurate real-time digital twins of the modular interiors, including detailed component metadata such as manufacturing date, material composition, and embodied carbon.

- 5G and IoT Integration: Leveraging a dedicated 5G network, real-time data from RTLS tags and environmental IoT sensors are securely transmitted to cloud platforms, providing actionable insights and enabling advanced adaptive control of the building environment based on dynamic usage patterns.

Implementation:

Republic of Ireland

Industry:

Circular Economy

Client:

Tech stack.

Hardware:

Software:

Infrastructure:

Database:

Outcome.

Impact & results.

Why it matters.

This project represents a transformative leap in sustainable interior construction, exemplifying the integration of cutting-edge technology and practical sustainability.

This innovative approach not only aligns with critical EU policies such as the EU Green Deal and Circular Economy Action Plan but also provides commercial building stakeholders with tangible, actionable pathways towards digitalisation, decarbonisation, and circularity. By enabling precise spatial management, real-time environmental responsiveness, and circular construction practices, this solution is making a measurable difference - both for client operational efficiency and environmental sustainability.

- Enhanced Circularity: Enabled component-level traceability and reuse, significantly reducing waste and supporting circular economy objectives.

- Real-Time Adaptability: Interiors can be quickly reconfigured to match evolving occupancy and operational requirements, dramatically enhancing flexibility.

- Accurate Embodied Carbon Tracking: Digital twin technology provides real-time insights into the embodied carbon and lifecycle sustainability of individual components.

- Improved Installation Efficiency: Modular components tracked digitally in real-time significantly streamline construction logistics and reduce installation times.